Fiberbed Industrial Mist Collectors capture, collect, and remove the liquid mists, aerosols, and sub-micron particles, that cause opacity, smoke, and blue haze. Air Clear’s Fiberbed Oil Mist Collection System technology eliminates aerosol mists and sub-micron particles from virtually any gas stream. EPA Air Pollution Control Technology Fact Sheet.

How an Air Clear FiberBed Mist Collection System Works:

Interception, Impaction & Brownian Diffusion

Air Clear’s Fiberbed Mist Collectors use the field-proven processes of Impaction, Interception, and Brownian Diffusion: Impaction occurs when particles in the 4 micron range is carried via inertia until they strike a filter fiber and are collected.

Interception occurs when microns (1-3 range) possess less momentum and typically follow the air stream until they deviate and graze the side of a filter fiber, removing them from the air stream. Brownian Diffusion is sub-micron particles (1 micron) that contain very little mass and follow the air stream.

As the air cools, random movement of particles slow down as they collide and coalesce until increasing in size enough to be filtered via impaction/interception. Air Clear Fiberbed Mist Collectors work to eliminate opacity and other industrial air pollution problems.

(7) 20,000 ACFM FIBERBED MIST COLLECTOR SYSTEMS ON TEXTILE PRINTING PROCESS. THESE UNITS HAVE BEEN IN OPERATION AT TIETEX TEXTILE PLANT SINCE 1992

Air Clear Fiberbed Mist Collectors are custom

designed for many Industrial Processes

- Asphalt processing

- Saturation

- Coaters

- Tank Vents

- Loading Stations

- Textile Processing

- Tenter frames

- Curing ovens

- Coaters

- Vinyl Manufacturing – Plasticizer emissions- Calendar lines

- Vinyl coaters-Battery cases etc.

- Pre-filter for other APC systems such as RTO’s

- Acid mist control

- Chemical process

- Fertilizer Manufacturing

- Emergency Air Filters

- Compressed air filters- Lube oil vents & reservoirs

- Electronics

- Etching

- Food processing

- Wood products -Plywood composite board Manufacturers

- Deep Frying

- Coffee Roaster

- Cocoa Processing

- Heat treating/annealing

- Metalworking (oil mist)

- Incinerator emissions

- Internal combustion engine crankcase vents

- Nuclear Waste filtration

- Precious metal recovery

- Printing-Web Offset

- Vacuum pumps

Air Clear’s Fiberbed Mist Collectors is proven Technology that offers a cost effective solution for the control of opacity and odors … Here’s why… Low capital cost when compared to other technologies.

Air Clear’s Coalescing FiberBed Filter Mist Collector Systems with a Granulated Activated Carbon Unit for

Peckham Industries in Athens, NY

Air Clear’s Coalescing FiberBed Filter Mist Collection Systems with a Granulated Activated Carbon Unit (GAC) is a potent approach to emissions control. This dynamic combination is in operation at Peckham Industries’ asphalt tank vent application in Athens, NY. Customized to fit our client’s needs in every way from the units footprint/placement to the precise sizing of their process flow, all while addressing the unique needs of emission/odor control. Air Clear’s FiberBed Filter units are the industry’s leaders in innovation and adaptability. While the Fiberbed Filter Mist Collector Unit removes aerosols, oil mists, and submicron particulate that cause opacity & odor, smoke, and “blue haze” emissions, our GAC is efficiently removing low-concentration Volatile Organic Compounds (VOCs) and excessive fugitive odors.

Air Clear’s Fiberbed Mist Collector Systems save customers money with its low operating costs

- Low initial pressure drop saves energy

- Fan motor runs on VFD to minimize power usage

- Long filter life means low replacement cost

- Collected liquids are often recycled saving material costs

- Low maintenance cost

Superior

Filter Performance

AIR CLEAR’S FIBERBED MIST COLLECTORS FILTERS ARE TESTED TO ASSURE MAXIMUM PERFORMANCE

- Air Clear Coalescing Fiberbed Mist Collectors are guaranteed to reduce stack opacity to 5% or less, excluding steam and uncondensed materials (see cooling for a discussion of this subject generally they achieve near zero opacity.

- Air Clear Coalescing Fiberbed Mist Collectors also offer very high particulate removal efficiency, in excess of 99%. They exceed the proposed OSHA requirement of 0.5 mg/m3 for indoor coolant/oil mist, and so are ideal for bringing Indoor Air Quality such as in, metalwork facilities into compliance.

- Air Clear Coalescing Fiberbed Mist Collectors are subjected to rigorous testing to ensure design level field performance. This testing is the most stringent in the industry. Test conditions are more demanding than most field conditions. Our customers are welcome to witness this testing in our shop.

- When tars, stone dust, talc, etc are present an Air Clear indexing prefilter is recommended to extend the life of the main filters.

Quality Workmanship

- Typically, the equipment is totally assembled for verification of fit of components. Shop assembly and testing allow Air Clear Engineers to verify performance prior to shipment. Any non-conformity is corrected before installation at the customer’s site.

- Our customers are encouraged to witness the shop testing. This is often an excellent opportunity for our customers to receive training on the equipment. This allows for the customer’s personnel to become comfortable and knowledgeable with the equipment before it’s shipped! Air Clear Systems are designed, manufactured, assembled, and tested prior to shipment to ensure trouble-free installation and start-up.

Shop assembly

- The fiberbed filters themselves are subject to a performance test procedure which checks the opacity control and pressure drop levels are within Air Clear’s design parameters.

- Benefits to the customer are:

- Faster, trouble free installation reduces installation costs

- Less downtime, increased revenue from production

- Higher on-line reliability from day one

- Complete Turnkey Service

- Remote Monitoring Services

- Field Support

- Engineering Services

Air Clear’s FiberBed Filter Oil Mist Collector System on Deep Fryer Application for B&D Foods in Boise, ID.

25,000 ACFM FiberBed Mist Collector System with indexing pre-filter on carpet manufacturing process La Grange, GA. Air Clear has three units operating at this plant. One unit outside and two units inside the plant.

Pilot Testing

Application

(Sales) Support

- Our technical sales team is committed to understanding the unique requirements of our customers on every project.

- Our technical sales team is passionate about investigating all relevant technologies before recommending a suggested solution.

- Air Clear’s Engineers constantly strive to improve existing designs.

- Our technical sales staff has a combination of 90+ years’ of technical expertise and unequaled dedication to customer service that sets Air Clear apart from the other.

The Importance of

Cooling The Process

Air Temperature

- Filters will not collect vapor phase molecules and particulate.

- Vapors must be cooled to between 120°F -150°F to condense most materials before entering filter for maximum efficiency. The cooler the exhaust, the more efficient the filter is.

Cooling Methods

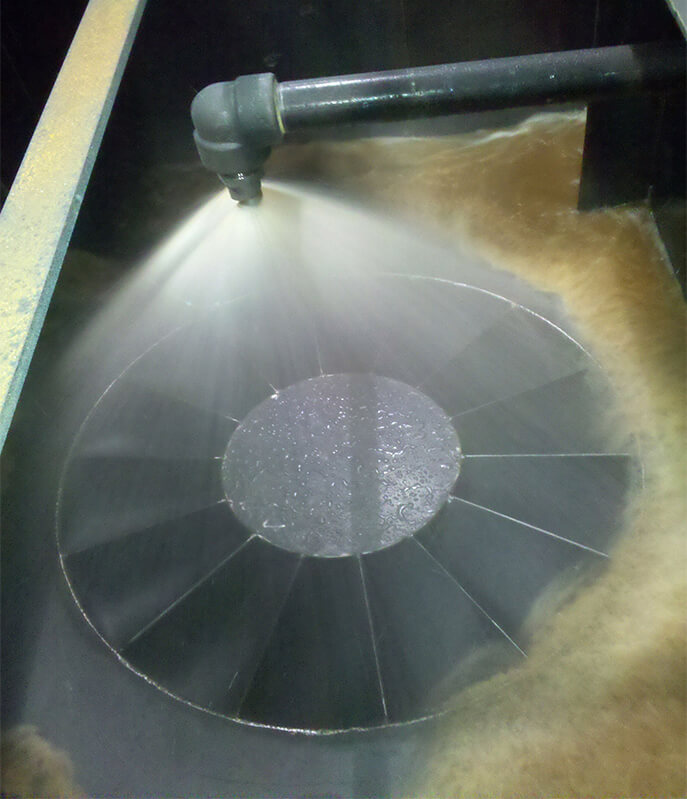

CYCLONIC SCRUBBER

For many applications such as asphalt coaters, saturators, textile tenter frames where the exhaust temperature is as high as 400°F adiabatic (water evaporation) cooling is used to lower the exhaust temperature. The bottom of the filter tank becomes the holding tank of the recycled water. The water is distributed over the Cyclonic tray which in addition to mixing the hot air and water it helps remove(scrub) solids from the exhaust.

AIR DILUTION COOLING

Dilution with ambient air controlled by a damper, or a temperature controller and actuated damper.

AIR-TO-AIR HEAT EXCHANGERS

Clean ambient air on one side of the air-to-air heat exchanger used to cool the hot process exhaust passing along other side of air-to-air heat exchanger.

COOLING COILS

Finned or smooth water cooling coils allow heat exhaust to pass outside the finned tube while cool water flows through it. The exhaust is cooled by transferring heat to the cooling water indirectly-without direct contact.

SHOP PHOTO OF AIR CLEAR’S CYCLONIC SCRUBBER FOR COALESCING FIBERBED MIST COLLECTOR SYSTEM

For years GAF has chosen to use AirClear’s FiberBedFilterUnits to remove 99.9% of the submicron particulate from their process stream.

Air Clear’s new FiberBedFilter Units are tied into GAF’s RTO, acting as prefilters. This will greatly extend the life of the media in their RTO by removing aerosols/particulate that would’ve eventually caused costly plugging in the RTO's media.

Air Clear’s Coalescing FiberBed Filter Mist Collector Systems for GAF in Minneapolis

The Air Clear installation team putting the final touches on our FiberBed Filter Unit

25,000 ACFM fiberbed mist collector w/ cyclonic scrubbing and pocket pre-filter system on Interface Flor, Georgia, USA carpet manufacturing process. Mist collector operates with 0% opacity.

Two (2) 20,000 ACFM Fiberbed Mist Collector Systems located on the roof of Everest Textile, NC. Both Air Clear Systems tested 0% Opacity.

(3) 25,000 ACFM fiberbed mist collector for carpet manufacturing process.

All of Air Clear’s filters are tested in house before they are shipped to assure maximum performance and quality.